Using different resin systems and materials of the substrate, the resin system is different, also lead to the activation effect of heavy copper treatment and the difference of the difference. Especially some CEM based composite sheet and high frequency in silver substrate specific, do electroless copper processing and need to take some of the more special processing methods about, if according to the normal chemical copper deposition is sometimes difficult to achieve good results.

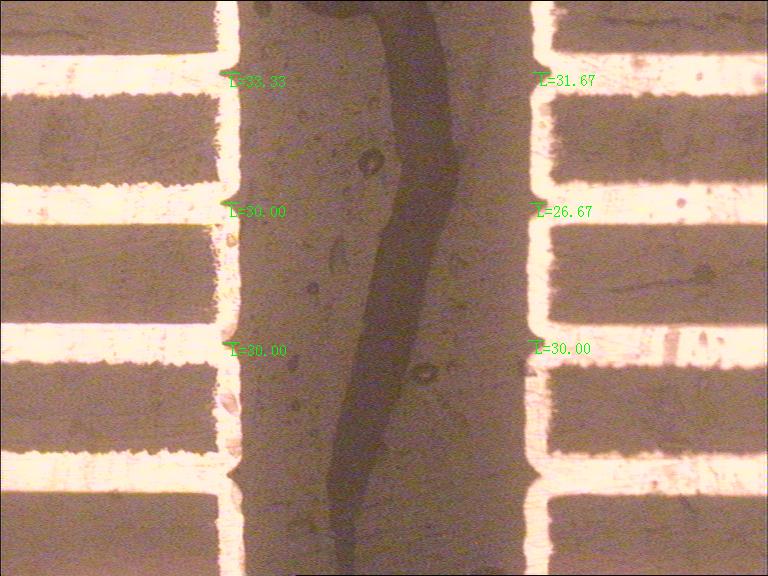

Pretreatment of substrate. Some substrates may ceiling tide and itself in the synthetic substrate pressure part of the resin curing bad, so the drill may because of the resin itself strength is not enough to cause the drilling quality is poor, drill dirt or hole wall resin tear to dig a grave and so on, as a result of this material were necessary baking should be. In addition, some multilayer laminates may also appear in the PP semi - curing film substrate area of the poor conditions, will also directly affect the drilling and in addition to the activation of the rubber slag, copper, etc.. Drilling condition is too poor, mainly for: resin dust hole, hole wall roughness, empty serious burr, burr hole, the inner copper nail head, glass fiber tearing section uneven in length and will cause some quality problems on electroless copper.

Brush plate in addition to treatment with mechanical method to substrate surface pollution and removal of orifice burr / Phi front outside, surface cleaning, in many cases, but also to clean and remove the role of dust in the hole. In particular, it is more important to do more than two sided plates without the process of removing the residue. Board and may be difficult to dust in the dust on the slag and to illustrate, we don't think the glue removing slag can go out hole glue residue and dust, in fact, in many cases, in addition to the glue process treatment effect is very limited, because in the bath will form small micelle, the bath treatment to the micelle adsorbed on the pore wall may be formed hole plated tumor, also in the follow-up process from the hole wall shedding. This may also cause hole point without copper, so the multilayer double-sided board, with the necessary machinery brush plate and high pressure cleaning is necessary, especially facing the development of the industry trend, orifice plate, and high aspect ratio is more and more common. Sometimes the dust in the hole is also a trend.

Proper glue residue removal process, you can greatly increase the pore binding force and inner connection reliability, but in addition to glue technology and related bath between poor coordination problems will also bring some occasional problems. In slag cement is insufficient, will cause the hole wall holes, the inner layer with bad, hole wall detachment, blow holes and other quality problems; in addition to the glue over may also cause holes in glass fiber protrusion, hole in the rough, the intercept point of glass fiber and copper infiltration and the inner tapered hole broken inner blackening of copper between were made into copper hole fracture or not continuous or folds in the plating coating stress increase in. The coordination control problem is also very important because of the addition of glue.

Swelling / swelling deficiency, may cause insufficient leavening glue residue; and a transition / swelling divides has changed in a fluffy resin, copper will not sink copper activation bad, even if the sink copper may also be in the process after resin subsidence, hole wall from other defects; in addition to glue groove, groove and new high processing activity may also be some connection with low degree of single functional resin double functional resin and three functional resin excessive glue phenomenon, resulting in the hole wall of glass fiber glass fiber is prominent, and difficult to activate chemical copper binding with resin between the worse, heavy due to copper deposition in extremely uneven substrate, electroless copper stress will increase exponentially, serious can sink copper after the hole wall copper chemical pieces fall from the hole wall clearly, causing the subsequent hole without copper.

Holes without copper, the PCB industry is not unfamiliar to the people; how to control? Many colleagues have repeatedly asked! Sliced to do a lot, the problem still can not be completely improved, always repeated, today is the process, and tomorrow is the production of the process. In fact, the control is not difficult, but some people do not have to adhere to the supervision and prevention of it, always piecemeal.

The following is my personal opinion and control method for the hole without copper. The reason for the production of the hole without copper is nothing more than:

1 drilling hole or coarse dust plug.

2 Shen copper liquid has air bubbles, the hole is not heavy on the copper.

3 hole in the line ink, without electricity protection layer, after etching hole without copper.

4 after settling the copper or the board electricity, the acid and alkali liquid medicine is not cleaned, the parking time is too long, resulting in the slow bite.

5 improper operation, in the process of micro corrosion stay too long.

6 plate pressure is too large, (from the design of punching hole near the middle conductive) neatly off.

7 plating solution (tin, nickel) penetration ability is poor.

In view of the reasons for the problem of no copper produced in the 7 holes.

1 on the easy to produce dust holes (such as 0.3mm 0.3mm below the pore diameter) to increase the high pressure water washing and in addition to the rubber slag process.

2 improve the liquid medicine activity and shock effect.

3 change printing plate and alignment film.

4 the extension of the washing time and the required number of hours to complete the transfer of graphics.

5 set the timer. 6 increase the explosion-proof hole. Reduce the stress of the board.

7 do regular penetration testing. Then know that there are so many reasons can lead to the hole without copper open, but also every section of the analysis? Whether it should go ahead of the prevention of supervision.